Image 1 of 5

Image 1 of 5

Image 2 of 5

Image 2 of 5

Image 3 of 5

Image 3 of 5

Image 4 of 5

Image 4 of 5

Image 5 of 5

Image 5 of 5

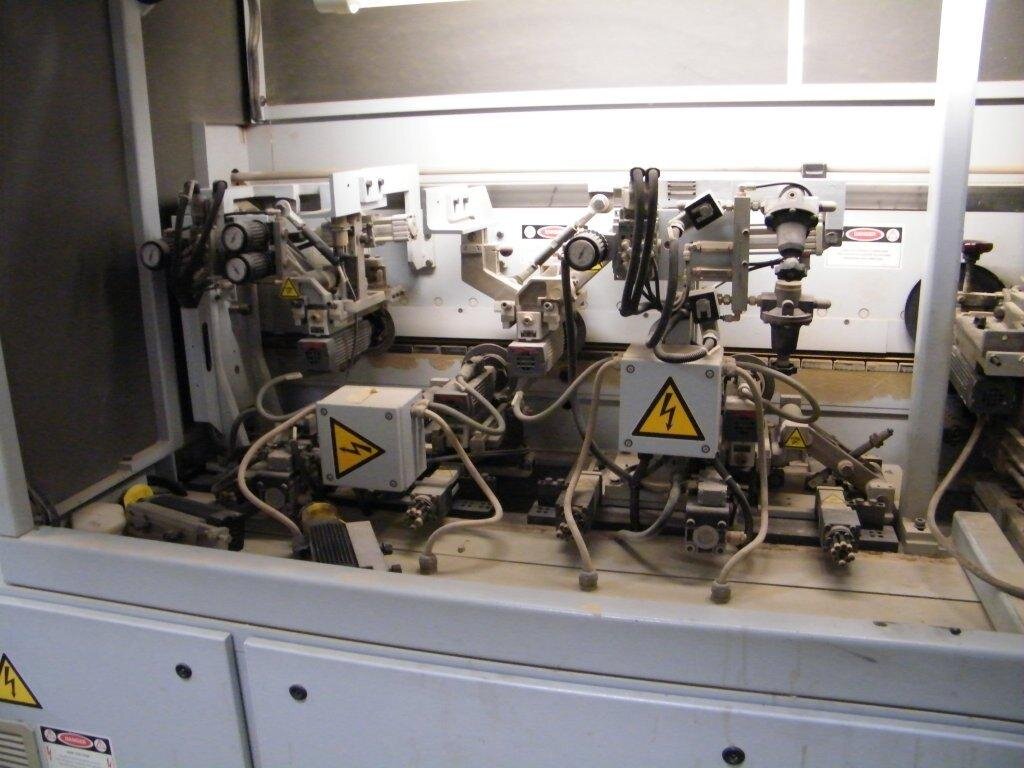

Homag KL/A3/S2 Edgebander with Premill (USED, 2000)

Homag KL/A3/S2 Edgebander with Premill (USED, 2000)

Model: Homag KL/A3/S2 Edgebander w/ Premill

SN: 0-200-08-XXXX

Year: 2000

460V; 60Hz; 3~

Stock#: 0812-16

Product Details

Edge thickness cap: 0.4 - 3 mm ,

min. panel width 55 mm (2-1/4"),

panel thickness 12 - 60 mm,

min. edge length 10-1/4".

Line control with "HOMATIC NC 21" controller features:

Keypad & LCD display, stores working programs and controls functions of workstations, allows fault diagnostic and comes with pendant for manual line control.

Equipped with:

Automatic coil feed magazine for coil material up to 1.5 mm thickness, Quick Melt glue system w/pre-melt granular hopper & roller applicator (reversible). Pneumatic pressure roll section with (1) large dia. driven & (2) pneumatically controlled idle rollers.

Workstations:

2-Position infeed fence;

Pre-milling with automatic jump.

Double motor front & rear end trim (0.7 HP - 12,000 RPM motor ea.), pneumatic chamfer setting.

Top & bottom rough trim (2 HP - 12,000 RPM motor ea.).

Top & bottom bevel & fine trim (0.6 HP - 12,000 RPM motor ea.), tiltable 0° - 30°, pneumatic exclusion from operator panel; all trim station motors are 200 Cy HF and equipped w/electronic brakes.

Last Station: Top & bottom oscillation buffing unit (0.3 HP - 1,650 RPM motors).

Top pressure beam with powered V-belt holddown, 80 mm wide Heavy Duty feed chain w/rubber pads, automatic chain track lubrication system, and 4 HP feed drive for variable feed speed of 23 - 98 FPM.

Homag KL/A3/S2 Edgebander with Premill (USED, 2000)

Model: Homag KL/A3/S2 Edgebander w/ Premill

SN: 0-200-08-XXXX

Year: 2000

460V; 60Hz; 3~

Stock#: 0812-16

Product Details

Edge thickness cap: 0.4 - 3 mm ,

min. panel width 55 mm (2-1/4"),

panel thickness 12 - 60 mm,

min. edge length 10-1/4".

Line control with "HOMATIC NC 21" controller features:

Keypad & LCD display, stores working programs and controls functions of workstations, allows fault diagnostic and comes with pendant for manual line control.

Equipped with:

Automatic coil feed magazine for coil material up to 1.5 mm thickness, Quick Melt glue system w/pre-melt granular hopper & roller applicator (reversible). Pneumatic pressure roll section with (1) large dia. driven & (2) pneumatically controlled idle rollers.

Workstations:

2-Position infeed fence;

Pre-milling with automatic jump.

Double motor front & rear end trim (0.7 HP - 12,000 RPM motor ea.), pneumatic chamfer setting.

Top & bottom rough trim (2 HP - 12,000 RPM motor ea.).

Top & bottom bevel & fine trim (0.6 HP - 12,000 RPM motor ea.), tiltable 0° - 30°, pneumatic exclusion from operator panel; all trim station motors are 200 Cy HF and equipped w/electronic brakes.

Last Station: Top & bottom oscillation buffing unit (0.3 HP - 1,650 RPM motors).

Top pressure beam with powered V-belt holddown, 80 mm wide Heavy Duty feed chain w/rubber pads, automatic chain track lubrication system, and 4 HP feed drive for variable feed speed of 23 - 98 FPM.

Homag KL/A3/S2 Edgebander with Premill (USED, 2000)

Model: Homag KL/A3/S2 Edgebander w/ Premill

SN: 0-200-08-XXXX

Year: 2000

460V; 60Hz; 3~

Stock#: 0812-16

Product Details

Edge thickness cap: 0.4 - 3 mm ,

min. panel width 55 mm (2-1/4"),

panel thickness 12 - 60 mm,

min. edge length 10-1/4".

Line control with "HOMATIC NC 21" controller features:

Keypad & LCD display, stores working programs and controls functions of workstations, allows fault diagnostic and comes with pendant for manual line control.

Equipped with:

Automatic coil feed magazine for coil material up to 1.5 mm thickness, Quick Melt glue system w/pre-melt granular hopper & roller applicator (reversible). Pneumatic pressure roll section with (1) large dia. driven & (2) pneumatically controlled idle rollers.

Workstations:

2-Position infeed fence;

Pre-milling with automatic jump.

Double motor front & rear end trim (0.7 HP - 12,000 RPM motor ea.), pneumatic chamfer setting.

Top & bottom rough trim (2 HP - 12,000 RPM motor ea.).

Top & bottom bevel & fine trim (0.6 HP - 12,000 RPM motor ea.), tiltable 0° - 30°, pneumatic exclusion from operator panel; all trim station motors are 200 Cy HF and equipped w/electronic brakes.

Last Station: Top & bottom oscillation buffing unit (0.3 HP - 1,650 RPM motors).

Top pressure beam with powered V-belt holddown, 80 mm wide Heavy Duty feed chain w/rubber pads, automatic chain track lubrication system, and 4 HP feed drive for variable feed speed of 23 - 98 FPM.

*This machine is offered in good running condition as taken from service and is subject to prior sale. Specifications are approximate and to the best of our knowledge. Verification is available upon request.